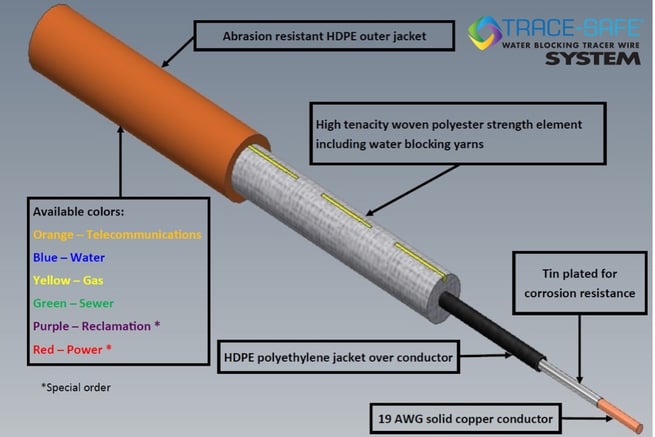

Neptco revolutionized the tracer wire market when it introduced Trace Safe, the world’s first tracer wire that incorporated water blocking technology to protect the solid copper conductor from water ingress. There are two distinct products that incorporate many of the same features but there are key differences.

While both products are available in all standard utility colors and have an HDPE outer jacket, water blocking yarns, HDPE wire insulation and a

Trace Safe gets its strength from the water blocking polyester core that surrounds the solid copper 19 AWG conductor. The core is made from high tenacity polyester yarns, like those found in car tires, that are treated with a super absorbent powder. If the out jacket is damaged, the super absorbent powders swell up like a baby diaper to prevent any moisture from meeting the solid copper conductor. This helps to ensure a long lasting reliable tracer wire.

The amount of core material is the distinguishing difference between the 1800 lb. RT products and 600 lb. TST products. Less core material lowers the cost of the TST products but each product has distinct applications that it is best suited for.

Also read: Bigger Tracer Wire Isn't Better and Here Is Why

The RT products have an overall rated strength of 1800 lb. and are ideal for horizontal directional drilling applications. RT products can be attached directly to the drill shaft and pulled back along with the conduit and

.

.

The TST products have an overall rated strength of 600 lb. and are

Trace Safe is a system which

So, which Trace Safe is best for you? It depends on the application. For directional drilling applications always choose the RT products, for everything else, the TST products.

For simplicity, some utilities prefer to stock only one wire and choose the RT products because of its universal utility. However, others are more explicit and will only use RT for directional drilling situations.

Consider the application and be sure to always use the Trace Safe connectors to complete the system.